ALKORDESIGN CHALLENGE

Dedalus Architects specified zinc for waterproofing the timber frame office building in Eeklo, Belgium. Not only for the roof, but also for the facade and bottom side of a unique construction detail. To be precise, waterproofing horizontally, vertically and even upside down!

To entirely cover the structure however, appeared not to be possible when using zinc. If you opt to use this traditional waterproofing material a ventilated air space must be provided underneath the zinc covering. This of course entails an opening for ventilation purposes underneath the roof edge, if not, condensation will occur. In the case of a building where the facade has to connect seamlessly with the roof and the underside, leaving an opening is not a possibility. So, despite the attractive appearance of zinc, a waterproofing solution with this material was not an option.

SOLUTION

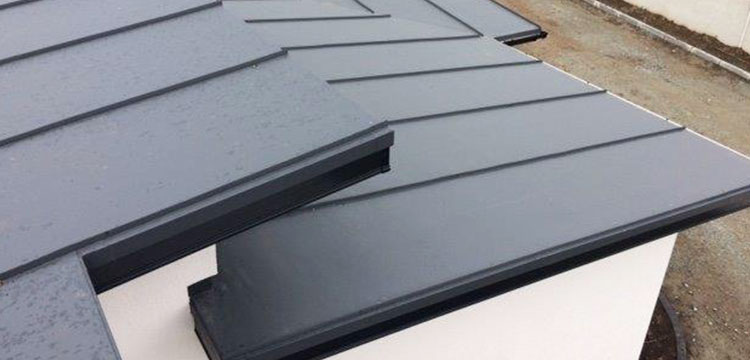

RENOLIT ALKORDESIGN standing seam imitation: a perfect solution for a difficult challenge. No ventilation needed, no connection problems, the same looks as a zinc roof and, above all, more cost effective! Not an easy job, though! At least if you want to have an aesthetically pleasing smooth result with a perfect finish at the corners and edges.

To get the perfectly fitting and tightly stretched looks, contact glue was used for the facades and ceilings, in order to prevent the membrane from sagging. On the roof edges and corners, where a seamless connection was required, metal sheet profiles were fixed first, then both ends of the membranes were welded onto the profile without an overlap. This resulted in perfectly straight edges! Afterwards, to get the look of real zinc, RENOLIT ALKORDESIGN profiles were welded onto the membrane and bevelled at the corners to have a seamless and continuous standing seam effect.

CHECK-OUT MORE PROJECTS WHERE RENOLIT ALKORDESIGN HAS SUCCESSFULLY BEEN USED: